Manufacturing processes and materials:

We’ve got them covered.

Always state-of-the-art: In the wake of production 4.0, we break new ground with you, initiating modern, efficient manufacturing processes for you and bringing innovative materials to the starting line. We have an expert for every area. Would you like support in converting to “Version 4.0”? Consider it done.

Where can we support you?

We are familiar with these processes:

- Plastic injection molding 1K/2K

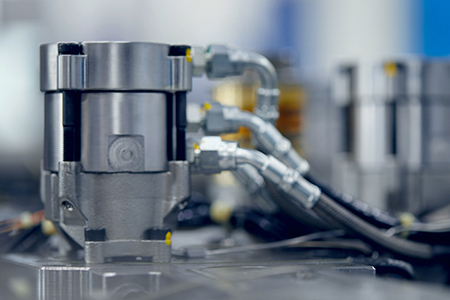

- Die casting

- Lifting/deep-drawing

- Punching and forming

- Welding, welded constructions, robot welding

- Metal forming, metal working, metal casting

- Lightweight construction/ carbon (preprag, pressing, moldings)

- Laminating

- Foaming

- ZB preparation, e.g. ultrasonic welding, assembly, laminating

- Painting

- KTL coating

- Cutting and sewing

- Electroplating

- Impregnation

- Coating